By Rick Phelps, Principal, Synchronous Solutions

We are accustomed to thinking about production’s physical Constraints in fabricating shops as being machinery or skilled craftsmen, but there are scenarios where the actual physical Constraint is space. The available space can limit production capacity when work needs to sit for a period of time, occupying limited space. This can happen when jobs need to be laid out on benches, or when product needs to sit to dry, cool, cure, set, or any similar time-based process.

When space is the Constraint, you need to think about this business differently, designing different metrics to align the business with this type of Constraint. Let’s use an example to explain how to do this.

Suppose we had a shop that needed to lay all the work out on benches to assemble by gluing and clamping pieces together. Once glued, the work had to set for a few hours for the glue to cure before it could be moved.

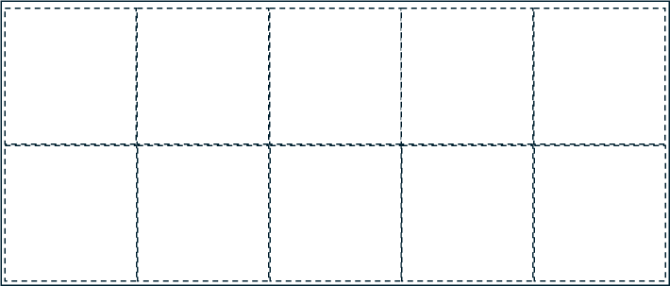

Take your layout space and divide it into a rational number of grids that are related to the size of your jobs. The example space below is divided into ten squares, and a sized typical job would take up one square, or 10% of the available space.

Large jobs might take up multiple squares.

Suppose the shop operates for one single eight-hour shift, and some jobs take 4 hours to assemble and cure, while others take six or eight hours.

What is the capacity of this shop?

The capacity of the shop is 80-square hours per day. [ten squares multiplied by 8 hours in a workday]

A ‘one-square’ job that takes four hours to assemble and cure consumes 4-square hours of capacity, or 5% of the shop’s capacity. [4-square hours divided by 80-square hours per day]

How can you calculate the relative profitability of jobs in this environment?

Supposed we had two jobs:

- A one square, 4-hour job, that carried $100T

- A three square, 6-hour job, that carried $400T

Which is the more profitable job for the business?

Job 1 brings in $25T per Square-hour

Job 2 brings in $22.22T per Square-hour

Therefore, Job 1 is the more profitable job.

Here is the math:

Job 1: $100T divided by 4 square-hours = $25T per square-hour

Job 2: $400T divided by 18 square-hours (3 squares times 6 hours) = $22.22T per square-hour

Supposed the Operating Expense for a day is $1,600.

What is the Profitability Index for each of the jobs?

Job 1 Profitability Index: 1.25

Job 2 Profitability Index: 1.11

Here is the math:

Breakeven is $1,600 divided by 80 square-hours = $20T per square-hour

Job 1: $25T per square-hour divided by $20T per square-hour breakeven = 1.25

Job 2: $22.22T per square-hour divided by $20T per square-hour breakeven = 1.11

Isn’t that interesting!

Synchronous Solutions is a company of Theory of Constraints experts that can help you understand how your business can REALLY make money!

Give us a call.